Robotic Welding Machine

"PRIMO" has delivered its state-of-the-art Robotic welding Machine solutions to Various Customers in different industrial segments for Robotic MIG / Arc Welding Machines & Robotic Handling Automation.

PRIMO has executed and supplied more than “100+ Robotic Welding Machine solutions” to Various customers in different industrial segments such as Automotive, Valve Manufacturing Industry, Heavy fabrication for railways, Yellow goods – Excavator manufacturer, Food Processing Industries, & Heavy Fabrication segments.

|

PRIMO Offers the following types of Robotic Welding Cell

|

|

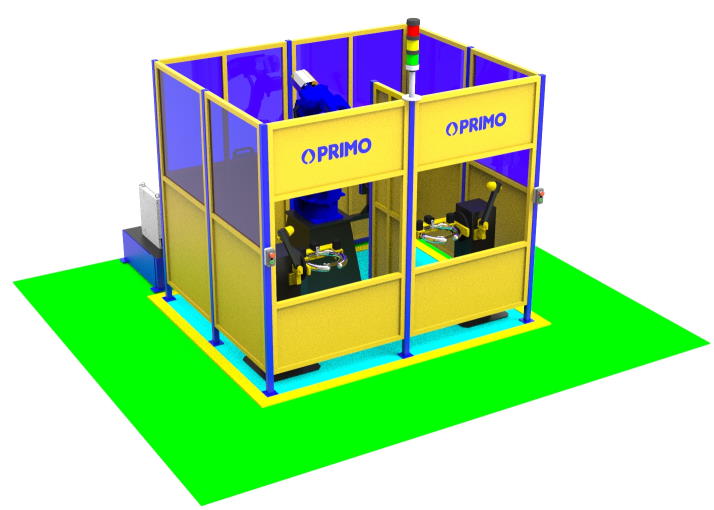

Basic Robotic welding cell with fixed Pedestal mounted Robot &Jigs & fixtures for Robotic component welding

Basic Robotic Welding Machine

|

|

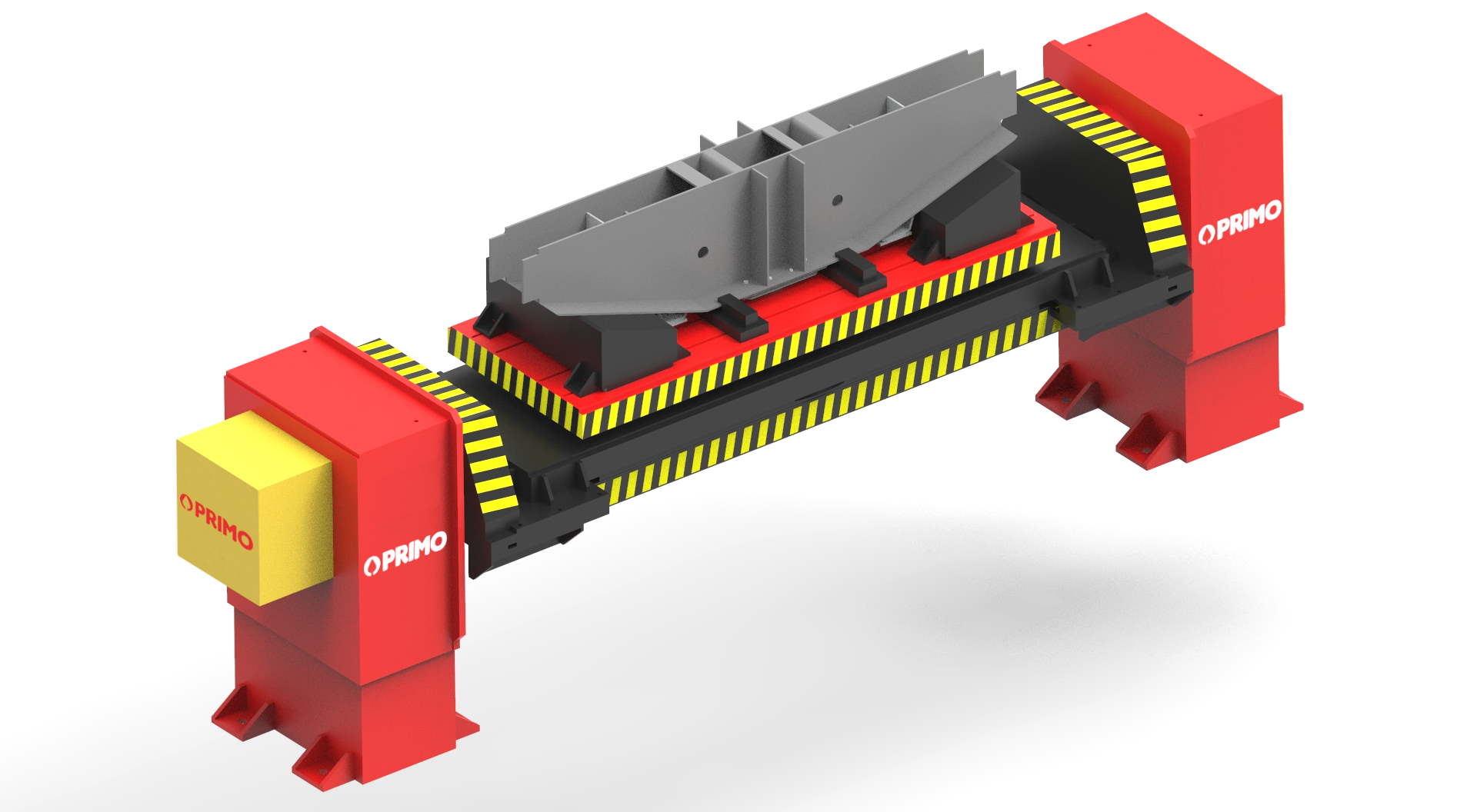

Moderate Robotic welding machine cell configuration with necessary welding Positioners of different types such as :

- Single axis robotic rotary positioner

- 2 Axis Sky Hook / L-Type positioner

- Head & Tail Stock Positioner

L-Type | Skyhook Robotic Positioner

Head & Tail Stock Cradle Type Robotic Welding Positioner

|

|

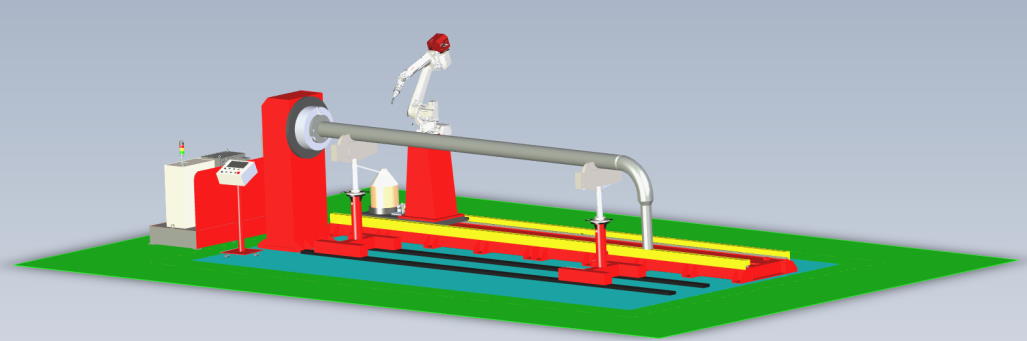

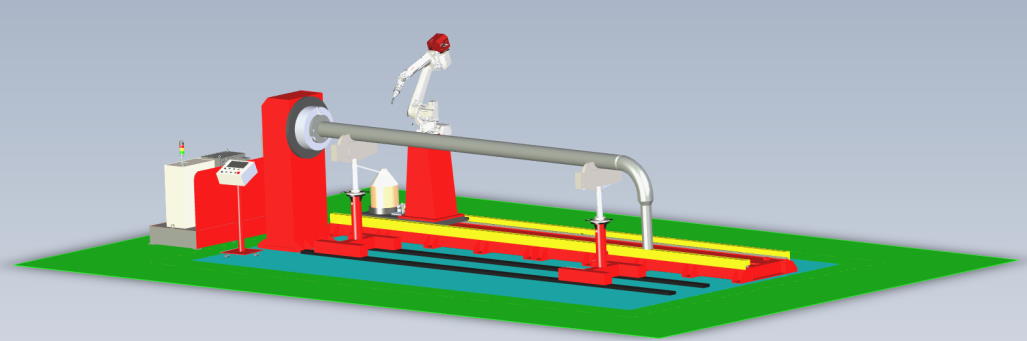

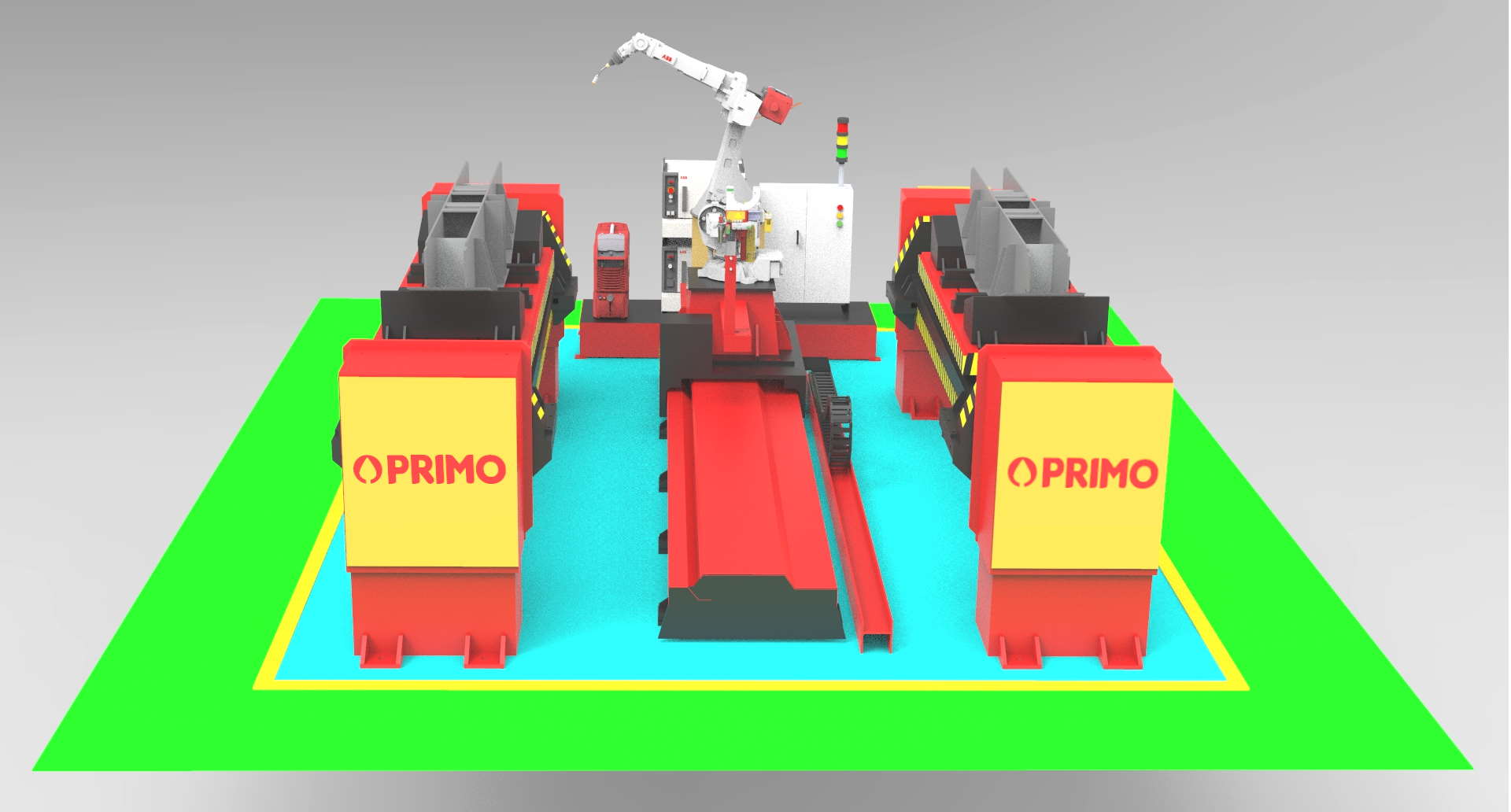

We can supply both Single station as well as Double station Robotic cell configured to suit your exact need. The cell may be accompanied with the following Robot accessories :

- Robot mounted on a fixed pedestal,

- Robot mounted on a 7th axis linear robot slider for moving between the stations & covering the entire length of the job.

- Robot mounted on a overhead gantry slider for moving between the stations & covering the entire length of the job.

7th Axis Linear Robot Slider

Multi Station Single Robot Welding Machine configuration

|

|

Highly advanced Robotic welding machine system setup with Multiple robots & multiple stations with combination of handling & welding robots to make it a “Unmanned Robotic Welding Machine” setup to eliminate human interventions.

|

|

We are specialized & equipped with necessary talents to incorporate any level of advanced configurations which can involve the following :

- 2 D Laser Scanners for Offline & Online profile & welding joint scanning functions for automatic correction of robot path according to component geometry & fit up variations.

- Vision Cameras for component identification & segregation inside the welding cell.

- Most of our cells are equipped with Advanced “Thru the Arc Seam Tracking” for implementing adaptive welding methods to counter the variation in the welding component.

- Start Point & End Point joint detection for exact weld path determination.

- Built-In Industry 4.0 features for monitoring various Robotic welding cell data such as Production , Quality & Maintenance related data at customer’s finger tips for quick assessment & decision making.

- Built-In Industry 4.0 features for monitoring various Robotic welding cell data such as Production , Quality & Maintenance related data at customer’s finger tips for quick assessment & decision making.

|

Please discuss with our Sales / Technical team about your exact requirement to offer our Best available Robotic Welding & Handling Automation Solutions.

OUR ACCOMPLISHMENTS

A Glimpse of Our 25 Years of Welding Automation Gallery