“WHY CHOOSE PRIMO” |

Our Robotic Welding Cells are designed and crafted to

meet the Highest level of precision, Highly engineered quality product

to meet any level of Industrial demands in a modern Welding / fabrication

Shop. We thoroughly understand our Customer’s

requirement, take it to the design table to arrive at the best optimized

configuration. So that our customers always get the maximum benefit in terms

of Welding Robot Cell Productivity, Rework free production, High Quality end

products without any Weld defects, Balanced / Optimized Robotic Welding

solution to meet the Return of Investment - ROI expectations of customer |

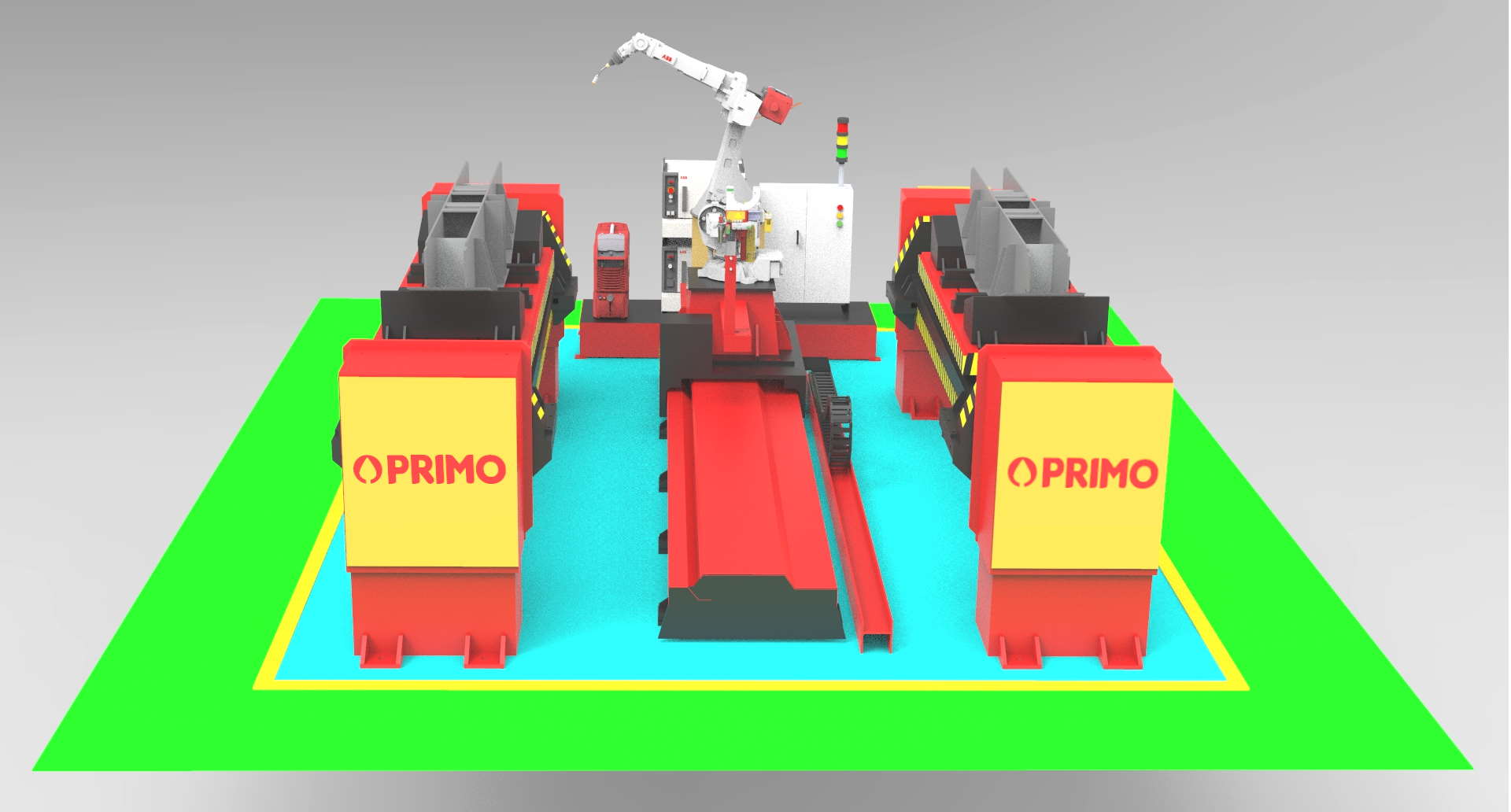

Versatile Dual Station Heavy Welding Robotic Cell

Customizable 7th Axis Robot Track Slider :

|

Brief Descriptions of 7th Axis Linear

Robotic Slider |

|

Robotic Slider with a required travel stroke. |

|

Our 7th Axis Robot sliders are designed,

manufactured to perfection to meet all the Modern day demands of High speed

Robot Positioning, Repeatability and longer service life. |

|

Servo Precision gear heads for swift and accurate

positioning of the slider unit. |

|

The Linear Positioning of the slider is controlled

by the Robot’s external axis setup with Synchronization enabled |

|

Robot is mounted on a Pedestal on to the top of the

saddle assembly. |

|

Robotic slider is equipped with provisions for

holding the Marathon / Jumbo Mig wire pack and the Torch Service Center unit

for moving along with the Robot. |

|

Complete insulation between the Robot base and the

pedestal for Electrical isolation. |

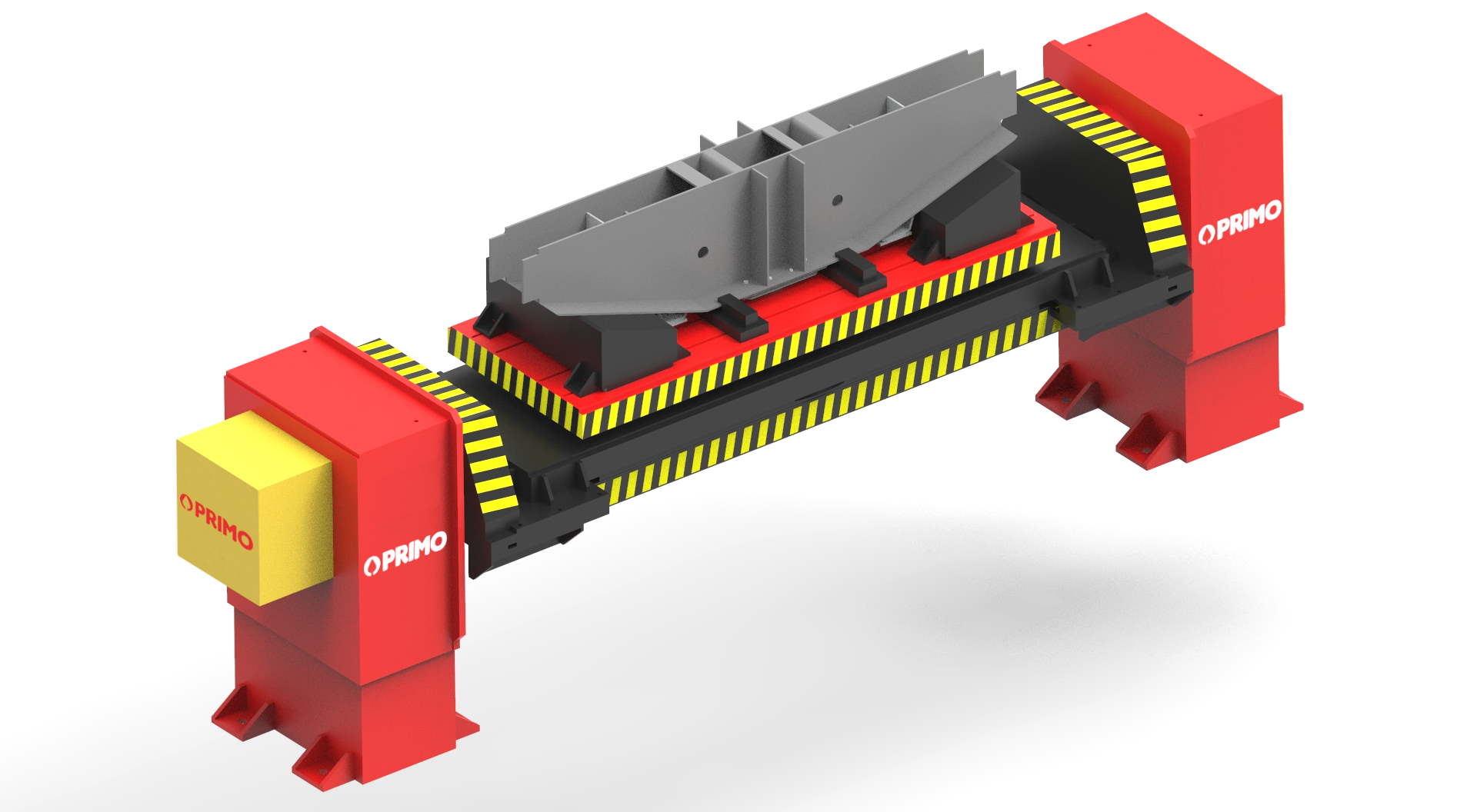

Head & Tail Stock Type Cradle Positioner:

|

Brief Descriptions of Cradle type Head & Tail

Stock Robotic Welding Positioner |

|

Dual Axis Cradle type

positioner for Tilting & Rotation of Pivot Beam component. |

|

Servo precision Gear

Heads for Tilting & Rotation axes. |

|

The Cradle type

positioner is designed and manufactured to handle component weights up to

1000 Kgs. We can design and manufacture up to 15 Tons. |

|

The Tilting axis can be

used for manipulating the component by +/- 100 Degree |

|

The Rotation axis can be

used for manipulating component from -10 Degree to +190 Degree |

|

Both the Tilting &

Rotation axis is controlled by the ABB Robot external axis setup with

Synchronization enabled. |

|

Tooling Fixtures will be

provided based on your component details. |